Technical data Nebulizer Agro

Dimension – all in mm ; Length x Width x Height 830 x 350 x 380 including 250 of spray lance. Weight in Kg 35. Movable by means of sturdy handles placed on top. Due to the compact size of the variable length spray lance, with the nozzle mounted, an opening of only 20 mm is sufficient.

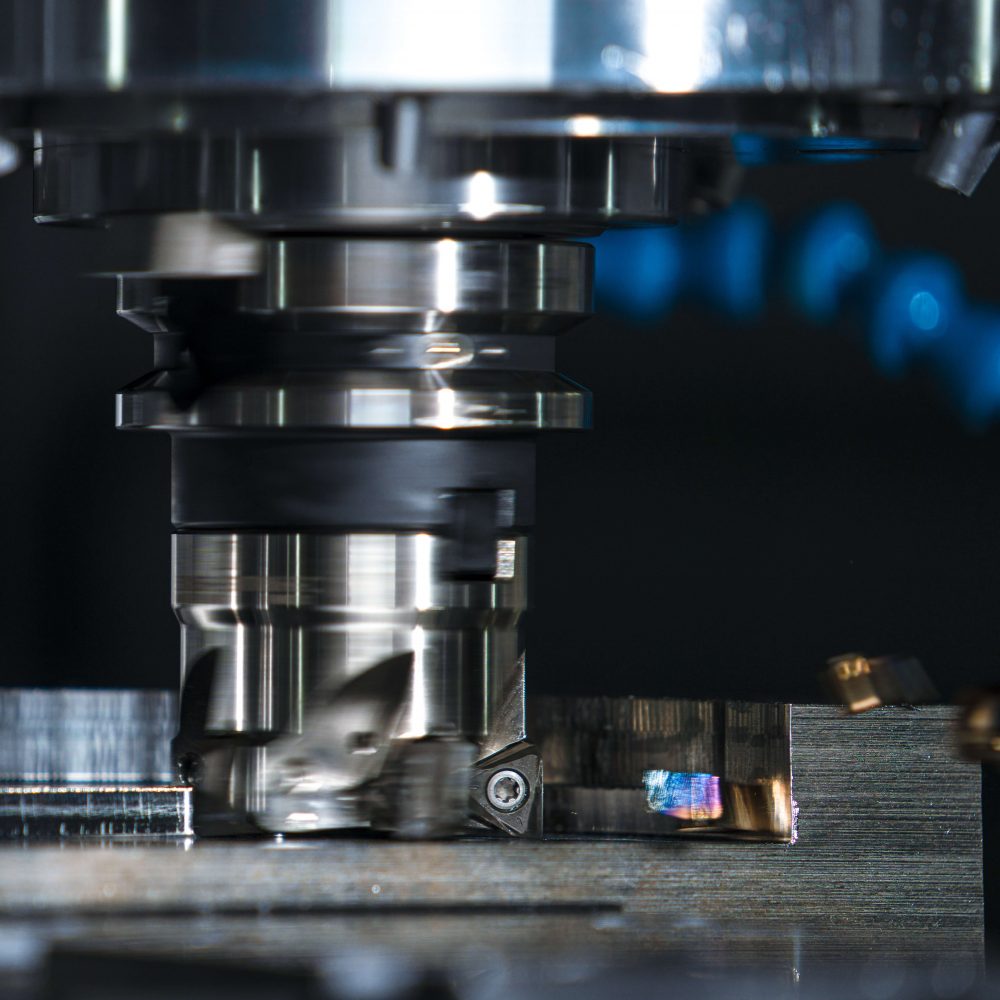

Effect – Applying germination inhibitors in potato storage areas. Efficient and safe energy management through the operating principle of evaporation without the addition of air or compressed air. In this way, the valuable resource remains within the storage facility. Maximum use of the existing ventilation capacity through a small, 20 mm passage opening. Innovative double-protected heating system with separate liquid transport. No fire hazard or harmful soot formation possible. (!) Required voltage 230 V, 10.2 A. The standard socket is more than sufficient. Electricity consumption ; 2350 W Maximum, at 300°C output temperature, and an operating pressure of 150 Bar. Due to the powerful suction, the trouble-free delivery head is max. 6 meters. This provides flexibility for working at heights and does not affect the atomization capacity. These special properties give the Nebulizer Agro its high efficiency!

Operation – Simplicity and ease of use are important features for safe operation; Large push buttons, 1 for 'on' in green with flashing function during heating, and 1 for 'off' in red with automatic return function, prevent operating errors. 2 Large rotary knobs with stepless adjustment for the Temperature, from 0°C to 300°C, as well as for the Pressure, from 50 to 150 Bar, both accurately displayed on the digital displays placed next to them. The dashboard is also equipped with an hour meter for the correct registration of any partial use. Switchable Acoustic Alarm of Max. 105 dB provides remote signaling of too high a temperature, for deviation from the set pressure value and, when the liquid in the can with the agent, has reached the lowest level. Minimal maintenance, no mandatory cleaning, 1.4 Sight® and Argos® proof.

The Canbase (supplied as standard) is a stable standard for the jerry can with the substance. This places the Can in an angle, so that the last remnant of liquid is accessible. Efficient suction ; the Can with the precious substance is empty to the last drop via a fine suction filter!

During many practical tests it has become apparent that the Nebulizer Agro has a pleasantly quiet sound level, which required listening carefully to hear how it works!

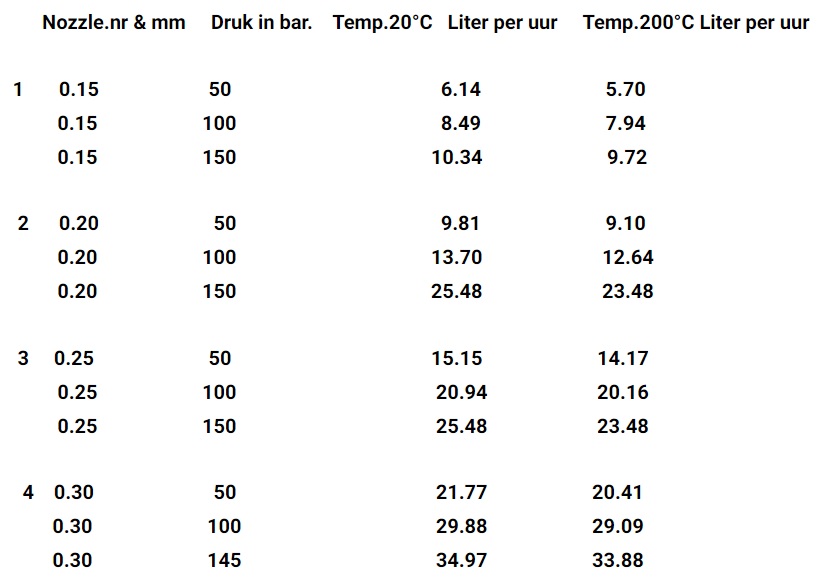

Abilities of the Nebulizer* Measured value using the product Argos® Producer UPL®

Overview diagram of Nozzle number with set values and yield in Liters per Hour.

The 4 Nozzles are standard equipment in the above sizes. Easy to change and packed in cassette for protection.

CE mark, number 36601, is in accordance with Machinery Directive 2006/42/00, and EMC 2014/30/EC.

The issued class is NEN/EN/ISO 12100 : 1210nl – NEN/EN/809 1998+A1 : 2009.

NEN/EN/ISO 14120 : 2015 NEN/EN/IEC 60204 – 1 : 2018

Test data Function Function Implementation and Droplet measurement at WUR Agrolab Wageningen, Agrosystems section. Execution by Dr. HJ Holterman, Sientist Agro.

Liquid used water. Set values, Temperature 300*C, and Working pressure 150 bar.

By having 2 laser beams cross each other, it is possible to measure the size of the droplets. Distance Nozzle to laser : 38 cm. We can perceive objects with the human eye if they are larger than about 40 µm. That is the thickness of a thin hair. Expressed in mm, this is 0.040 mm. 1 µm (microns) is 0.001 mm.

→ 10 % of all droplets have a measured value of 3.2 µm to 7 µm. Or 0.0032 to 0.007mm. → 80 % of all droplets have a measured value of 7 µm to 33 µm. Or 0.007 to 0.033mm. → 10 % of all droplets have a measured value from 33 µm Or from 0.033 mm

Technical data HINT High Tech Nebulizer Transporter ; Dimensions in mm ; Length x Width x Height 1020 x 690 x 340. Weight 15 Kg. Easily detachable service handle with L-shaped handle to move Transporter, and for high/low adjustment. Length 1400mm. This Transporter has been specially developed for the use of the Nebulizer*. Due to an excellent weight distribution, it can be handled safely and with 1 person. The robust stainless steel mechanism is multifunctionally adjustable in height and tilt angle. Airless tires make it possible to move over any terrain and the twisting action of the mechanism absorbs shocks. Due to this solid base and the many adjustment options, the Nebulizer* can reach any opening. During the operation of the machine, a brake ensures to stabilize it in the right place for safe operation.

Due to the high prices of the sprout inhibitors, we have gone to great lengths to make the entire process as efficient as possible. To prevent losses, a CanBase has been developed, which forms the basis for the can with the drug. By placing it at a fixed angle, we make use of the possibility to reach the lowest level. Due to the powerful suction with the filter, not a drop is lost.

Circular Design.

Servatech BV has the Circular Economy as the starting point for its products. In this system, no finite resources are consumed. All used materials can be reused at the end of the expected life of 30 years.